Zircaloys have anisotropic bodily, mechanical, and chemical properties. Within the oxide layer, the alloying elements affect the atomic transport such that the alloying concentration determines the corrosive behavior, with excessive alloying concentrations (above ∼zero.6%) providing safety in opposition to oxide growth. Today, Zircaloy-2 and Zircaloy-four are broadly used.

The oxidation course of and the nature of the oxide layer on a zirconium alloy sample are schematically illustrated in Fig. 6 .

Laser cladding has resulted in surfaces with superb finish, good homogeneity, and very low porosity. Common supplies used for cladding embrace carbides, iron-based mostly alloys, nickel base alloys, and cobalt base alloys. The manufacturer of the flamable panels wrapped around Grenfell Tower has claimed different materials had been liable for spreading the hearth that claimed seventy two lives and said it may have been put out with a handheld fire extinguisher.

Modified low-tin alloys can be used both as an entire replacement for the Zry tube wall or as a thin outer skin on normal Zry substrate tubing. 1.5% tin, and the steadiness being iron, nickel, and chromium. Its industrial identify is Zircaloy, or Zry for brief.

The Building Research Establishment (BRE) has been commissioned to undertake this challenge. This programme is on-going and exams are expected to conclude in the summer.

tube. Energy, from fission, is generated approximately uniformly all through the gasoline pellets. Heat is extracted at the rod floor by the coolant circulate. The temperature at the hottest level, at the pellet centerline, is typically within the range 800–a thousand °C, depending on the power degree. The metallic cladding is an efficient conductor, so the temperature rise throughout the wall is just a few tens of levels.

The interaction that gasoline cladding tubes expertise because of the fission products on the internal surface is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are a number of the fission products which contribute strongly to the SCC process.

2 Cladding

In other modifications, the sponge zirconium is alloyed with iron or tin to improve oxidation resistance with out affecting the softness that provides immunity from PCI. scale that grows around them during in-reactor operation. This lack of the insulating properties of the oxide is believed to accelerate the corrosion fee.

The authorities’s constructing security programme has centered primarily on instant interim mitigation actions and permanent substitute of unsafe aluminium composite material (ACM) panels on excessive-rise buildings due to the acute dangers posed by such panels.

The spread of the fireplace up the skin wall, if any, was then monitored. The Independent Expert Advisory Panel additionally suggested the division to establish a research challenge to check and improve the proof out there on the behaviour of a spread of non-ACM supplies used in cladding systems when subjected to fireside.

These frameworks have been utilized and peer reviewed inside the scope of fire analysis research on the fire efficiency of aluminium composite panels and insulation materials at The University of Queensland and the University of Edinburgh. This giant scale check, undertaken by the Fire Protection Association (FPA), examined a HPL panel system with stone wool insulation, in accordance with British Standard 8414. This check involves building a 9-metre excessive wall with a whole cladding system mounted to it - including panels and insulation. This was then subjected to a fireplace designed to copy the circumstances in which a extreme fireplace breaks out of a window.

The interplay that fuel cladding tubes experience as a result of fission merchandise on the internal floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission merchandise which contribute strongly to the SCC process.

The impact of lack of metal by internal or outer corrosion is less necessary for thick cladding than for thin-walled tubing. For the same external loading, the stress produced within the cladding, both external from the coolant or internal from fission-product swelling of the gas, is reduced in proportion to the wall thickness. However, thick cladding is detrimental to neutron financial system, increases the quantity of the reactor core, raises gas temperature, and prices greater than skinny-walled tubing. The compromise between these competing calls for has produced wall thicknesses of ∼0.9mm in BWRs and ∼0.7mm in PWRs. is produced and the risk of a large secondary hydriding failure is elevated.

Moore-Bick has confronted widespread calls to conclude in his interim report – anticipated next spring – that the £10m refurbishment, utilizing extremely flamable cladding panels, was in breach of building rules. But he has also heard conflicting proof about whether the hearth brigade ought to have tried to order a full evacuation before the constructing was engulfed in flames trapping and killing households and associates who huddled together in flats. Earlier in Wednesday’s listening to firefighters blamed the Royal Borough of Kensington and Chelsea for failing to make an evacuation plan for Grenfell Tower, despite expert advice taken before the disaster and legal obligations making clear it was essential. The performance of the uPVC home windows in the fourth ground flat where the fireplace began, the synthetic insulation and different decorative cladding panels across the rest of the constructing have been effectively answerable for spreading the fire, he mentioned.

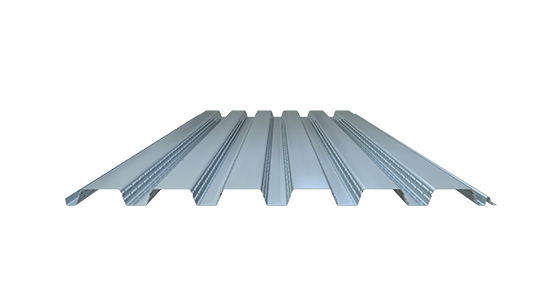

Metal is the most vitality-environment friendly and sustainable constructing supplies available. Next to this it is nearly fully recyclable and current metallic coils comprise a high recycling content up to ninety five%. The engineering of our supplies also makes our cladding a powerful resilient type of exterior overlaying . The bonding agent reinforces the picket components, and our additives improve the cladding’s weather resistance.

With the event of an equilibrium pore and crack structure in the oxide layer, the oxidation price effectively turns into linear, a characteristic function of the submit-transition oxidation behavior. Alloying parts, notably tin, niobium, and iron, current in the α-solid resolution strongly affect both the kinetics and the mechanism of oxide progress in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting efficiency requirements.

The joint is then brought on by a deformation-induced melting tub. The melt layer is quite skinny; for instance, when cladding an aluminum alloy it is about zero.5–4μm (Kreye 1985, 1997 ). The dilution of the molten zones results in plane or corrugated interfaces.

Phase transformation of Zirconia is, nevertheless, of great concern. Zircaloys also endure from unhealthy creep charges. In contrast to surface-layer welding, explosive welding causes no change in microstructure, and corrosion resistance of the layers is not affected (Pocalco 1987 ). ions from the surroundings to the reaction front on the metallic/oxide boundary.

Non-aluminium composite material cladding

The unfold of the hearth up the skin wall, if any, was then monitored. The Independent Expert Advisory Panel also suggested the division to ascertain a analysis project to check and enhance the proof available on the behaviour of a variety of non-ACM materials used in cladding techniques when subjected to fire.

Modified low-tin alloys can be utilized both as a whole replacement for the Zry tube wall or as a skinny outer pores and skin on normal Zry substrate tubing. 1.5% tin, and the balance being iron, nickel, and chromium. Its commercial name is Zircaloy, or Zry for short.

Phase transformation of Zirconia is, however, of nice concern. Zircaloys also suffer from unhealthy creep charges. In distinction to surface-layer welding, explosive welding causes no change in microstructure, and corrosion resistance of the layers isn't affected (Pocalco 1987 ). ions from the surroundings to the reaction front at the metal/oxide boundary.

The joint is then attributable to a deformation-induced melting tub. The soften layer is kind of thin; for example, when cladding an aluminum alloy it's about zero.5–4μm (Kreye 1985, 1997 ). The dilution of the molten zones results in plane or corrugated interfaces.

The oxidation course of and the nature of the oxide layer on a zirconium alloy pattern are schematically illustrated in Fig. 6 .

As a remedy, speedy cooling of the Zry ingot during fabrication (called beta quenching) produces a much finer intermetallic precipitate population. This distribution of the transition metals maintains the power of the Zry however improves its corrosion resistance, presumably by short-circuiting charge-transport paths between the scale surface and the metallic–oxide interface. In order to remove waterside corrosion of cladding as a life-limiting course of, modified Zircaloys have been developed. Under PWR water situations, lowering the tin content material of Zry to 1% and including a comparable concentration of niobium produces an alloy with a corrosion rate several instances decrease than that of the usual Zry.

Zircaloys have anisotropic physical, mechanical, and chemical properties. Within the oxide layer, the alloying components influence the atomic transport such that the alloying focus determines the corrosive conduct, with high alloying concentrations (above ∼zero.6%) providing protection towards oxide development. Today, Zircaloy-2 and Zircaloy-4 are extensively used.

tube. Energy, from fission, is generated approximately uniformly all through the gas pellets. Heat is extracted at the rod surface by the coolant flow. The temperature at the hottest point, on the pellet centerline, is often in the range 800–one thousand °C, depending on the power degree. The metallic cladding is an effective conductor, so the temperature rise throughout the wall is only some tens of degrees.

Grenfell inquiry chair click site demands end to 'stay put' advice for all high-rises

The oxidation process and the nature of the oxide layer on a zirconium alloy sample are schematically illustrated in Fig. 6 .

After melting and bonding by the laser, the alloy layer was 1.5 mm thick and had little or no dilution from the steel. The resulting surface had glorious wear resistance. Architectural metallic cladding is the collective term for exterior building cladding made from coated metallic. In the final decades steel became one of the well-liked building materials for the constructing envelope amongst architects and builders.

The prime plate hits the bottom plate with a velocity of one hundred–1000 ms −1 , and pressures are within the vary of 10 to 100 kbar. Under sure conditions a superheated layer of material types within the contact space.

The government’s constructing safety programme has focused totally on immediate interim mitigation actions and everlasting substitute of unsafe aluminium composite material (ACM) panels on excessive-rise buildings because of the acute dangers posed by such panels.

With the development of an equilibrium pore and crack structure in the oxide layer, the oxidation price effectively becomes linear, a attribute function of the post-transition oxidation behavior. Alloying components, notably tin, niobium, and iron, current within the α-solid solution strongly influence both the kinetics and the mechanism of oxide development in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting performance requirements.

Zircaloys have anisotropic physical, mechanical, and chemical properties. Within the oxide layer, the alloying elements affect the atomic transport such that the alloying focus determines the corrosive habits, with high alloying concentrations (above ∼0.6%) offering protection against oxide development. Today, Zircaloy-2 and Zircaloy-four are broadly used.